John Tojeiro also designed the body, a sleek shape reminiscent of the Ferrari 166 Mille Miglia.

Design work on Ford’s Challenger V-8 engine began in 1958 under the leadership of Robert F. Stirrat. Weight reduction became a main objective during this period, and Ford aimed at producing a cast-iron engine that could compare in weight with an aluminum power unit of similar displacement. The decision to use cast iron was based on such advantages as the graphite content in its matrix, which serves as a lubricant in itself and also attracts and holds minute particles of engine lubricant, thus further reducing engine wear. Cast iron also has excellent sound-damping qualities, and tends to damp vibrations. Thermal expansion characteristics are nearly ideal, assuring proper clearances at all operating temperatures.

Aided by Ford Foundry’s latest techniques in thin-wall casting, with extensive use of resin-bonded cores, Stirrat came up with an engine that weighed only 450 pounds complete.

Its dimensions are very compact—8.93 inches high, 16.36 inches wide, and 20.84 inches long. A study of the short and stiff five-bearing crankshaft indicated that about 70% of the total unbalanced couple could be balanced by means of normal crankshaft counterweights. Two external counterweights provide the other 30%, one mounted in front of the timing sprocket and the other as an element of the flywheel. No vibration damper was needed. Crankshaft stiffness is such that the fourth harmonic occurs beyond the normal engine operating range.

Shelby modifications include higher compression, a hotter camshaft and a four-barrel carburetor (Ford or Holley). As a power option, four Weber carburetors will be available, and in racing tune the engine puts out 355 bhp.

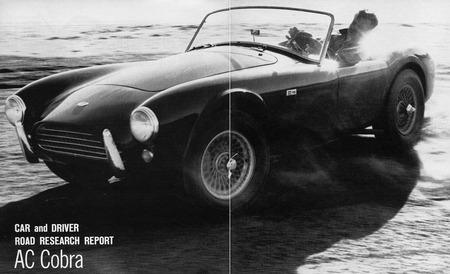

The cars are shipped complete, except for engine and transmission, from AC, and engines and transmissions are shipped from Ford to its dealers whom Shelby has authorized to carry out the installation. Our test car had the lesser state of tune (and had not been test-driven by Carroll Shelby). Even with the mild engine, the torque characteristics were incompatible with most street driving, with a flat spot below 2,000 rpm and a really devastating noise at maximum torque. We suspect that the valve clearances were off on the test car, not only because of the terrific clatter but also because the engine seemed to peak out before the 7,000-7,200 rpm that Shelby claims to get with ease.

During our acceleration tests, upshifts were made below 6,000 rpm, as no improvement could be seen by staying longer in the lower gears. The gearbox was not fully run in on the test car, and its movements were inclined to be stiff. The short lever and its precise gate should be just perfect, though, after another 5,000 miles or so.

As has every other American high-performance car of recent times, Ford uses a Warner all-synchromesh transmission. The gear ratios are very well chosen, and close enough for racing, but it is a question whether a five-speed unit would not give better results. With the 3.5-to-one final drive, a starting gear is needed, and with a higher ratio, the car would be undergeared for many circuits. Perhaps next year will see further experiments in this direction.

Placed in a chassis with less of a racing tradition, the power of the V-8 Ford would have been an embarrassment rather than an advantage. The center of gravity is located slightly towards the rear, and the rear wheels have a negative camber of about 3 degrees in their neutral position, with just a trace of toe-in. This setup is obviously made to reduce or annihilate oversteer–but it is still the tail that begins to swing wide when the limit is approached. Correction of such slippage is easy enough, with judicious use of power.

Leave a Reply